My Lens on the Week - Salt vs. Lithium: The Battery War Has Already Started

The biggest battery company in the world, CATL (宁德时代) which raised nearly $5 billion in a secondary Hong Kong listing this week, just dropped a bombshell on the energy storage industry.

The biggest battery company in the world, CATL (Contemporary Amperex Technology Co.), just dropped a bombshell on the energy storage industry. While everyone else is chasing marginal lithium improvements, they're redirecting half their gigafactory capacity to sodium-ion batteries. Let me break this down from first principles.

🔬 CATL Battery Technology

To understand CATL's innovations, let's deconstruct their battery technologies into fundamental components:

What is a Battery?

A battery stores chemical energy and converts it into electrical energy through electrochemical reactions between its components:

Anode (Negative Electrode): Typically made of materials like graphite, where lithium ions are stored during charging.

Cathode (Positive Electrode): Often composed of lithium metal oxides, which release lithium ions during discharge.

Electrolyte: A medium that allows the flow of lithium ions between the anode and cathode.

Separator: A barrier that prevents physical contact between the anode and cathode while allowing ion flow. (More here)

How Does It Work?

During charging, lithium ions move from the cathode to the anode through the electrolyte, storing energy. During discharging, the ions move back to the cathode, releasing stored energy as electricity.

⚙️ CATL's Key Battery Technologies

A. Condensed Battery

Energy Density: Up to 500 Wh/kg, significantly higher than traditional lithium-ion batteries.

Innovation: Utilizes biomimetic condensed-state electrolytes forming a self-adaptive net structure, enhancing ion transport and structural stability.

Applications: Suitable for electric aircraft due to high energy density and safety standards.

B. Shenxing Fast-Charging Battery

Charging Capability: Adds 520 km (323 miles) of range in just five minutes.

Performance: Maintains high charging efficiency even at -10°C, reaching 80% charge in 15 minutes.

Technology: Incorporates nano-crystallized cathodes and superconducting electrolytes to enhance ion mobility.

C. Sodium-Ion Battery (Naxtra)

Energy Density: Approximately 175 Wh/kg, comparable to lithium iron phosphate (LFP) batteries.

Advantages: Utilizes abundant and cost-effective sodium, offering improved safety and performance in low temperatures.

Production: Mass production planned to commence in December 2025.

Basically, what they focus is;

Material Choice: Exploring alternative materials like sodium to address resource scarcity and cost.

Structural Design: Innovating at the molecular level to enhance performance and safety.

System Integration: Developing batteries that meet specific application requirements, such as aviation standards.

Now, let’s get back to the story.

The Sodium Advantage: It's Basic Physics and Economics

First, let's be clear about what's happening: Earth stores 1,200 times more sodium than lithium, scattered across every continent. When the world's lithium titan tells you it plans to swap half its output for sodium, that's not a casual strategy shift - it's throwing a Molotov cocktail at the lithium status quo.

Raw sodium costs $0.3/kg versus lithium's $6/kg. But the sodium advantage goes beyond simple material costs. CATL's SIB-4 launch taps a massive, low-IP resource pool, slashing geopolitical chokeholds on South American lithium mines and handing China's battery sector fresh leverage.

Performance Metrics That Actually Matter

Forget the marketing hype. Here's what matters:

Safety: CATL's Naxtra batteries survive drill, puncture, and cutting without ignition. They endure temperatures up to 260°C (versus 165°C for lithium) before self-heating. They've removed fire risk, which slashes vehicle recall and insurance premiums while clearing regulatory hurdles for high-density urban and underground deployment.

Extreme Temperature Performance: Second-gen SIBs operate down to -40°C, while Li-ion chokes around -20°C. This opens untapped EV markets in Alaska, Siberia, and Arctic mining camps without bulky heater packs.

Fast Charging: With 5C charging capability hitting 30% to 80% in ten minutes, sodium-ion cells allow OEMs to potentially shrink or even skip high-power supercharger investments. Some claim 520 km range in just 5 minutes - blowing past BYD's 400 km benchmark.

Cycle Life: CATL has demonstrated 10,000 charge-discharge cycles, suggesting battery packs that could outlast the vehicles they power. Companies like Natron claim their sodium cells soak and expel energy 10× faster than Li-ion, making them ideal for data centers, 5G towers, and microgrids that prioritize cycle life and instant replenishment.

The Manufacturing Reality - It's About Scale

CATL isn't simply selling one cell type - they're offering a complete toolkit. They blend sodium-ion with LFP or NMC to tailor range, cost, safety, and fast-charge capabilities. OEMs get bespoke packs instead of one-size-fits-all solutions.

CATL will start mass production of Naxtra sodium-ion cells this December. This isn't a lab experiment - it's a factory-line reality that will inject ultra-low-cost chemistries into the market before year-end. Meanwhile, BYD's parallel commitment to a 30 GWh SIB gigafactory by 2027 suggests that if sodium cell costs tumble 70% with volume, they'll crush rivals still burning cash on lithium-nickel stacks.

The Real Existential Challenge for Western Players

At 500 Wh/kg, CATL's condensed battery technology far surpasses Tesla's 250 Wh/kg 4680 cells. This energy density gap cements China's pricing power and will force every automaker to renegotiate supply deals or risk being stuck with underpowered cells.

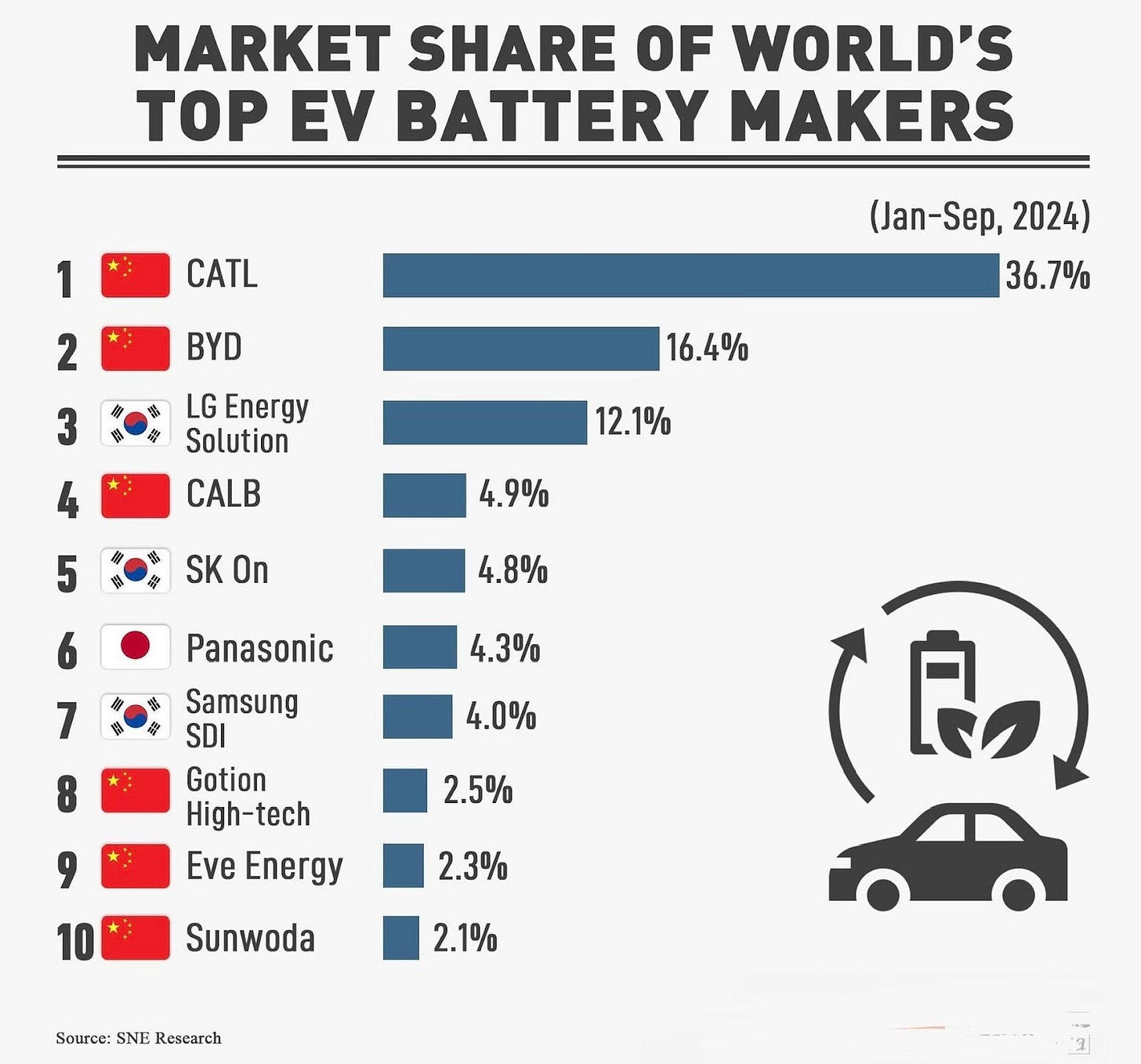

The scale challenge is brutal: Six of the top ten battery suppliers are already Chinese. Naxtra widens this advantage. R&D, talent, and M&A will increasingly centralize in China, forcing Western OEMs to choose between developing trailing in-house programs or partnerships that cede control.

What This Means for Us as Investors

Follow the Manufacturing Shift: Mass production plans indicate CATL has already sized up gigafactory expansions for sodium-ion by 2025. Watch capex announcements - they signal major capacity additions and downstream value capture.

Target the Supply Chain: Companies developing advanced electrode materials, hard carbon production, and cell assembly equipment optimized for sodium chemistry will capture outsized value as this transition accelerates.

Bet on Thermal Resilience: SIBs demonstrate superior performance in wildfire-prone regions like California and Australia, creating opportunities for utility and warehouse contracts where thermal safety is paramount.

Watch for U.S. Manufacturing Plays: Natron's 24 GWh plant in North Carolina and 0.6 GW hub in Michigan represent a geopolitical countermove. A domestic SIB supply chain would allow grid operators and telecoms to reduce dependence on Asian supply chains.

Consider the Organic Cathode Moonshot: Dincă Lab's TAQ (bis-tetraaminobenzoquinone) breakthrough could turn sodium-ion batteries from "hauling coal wagons into dragsters." This metal-free, insoluble cathode material with nearly 100% utilization could enable sodium cells to eventually surpass lithium in performance at one-third the cost.

The Battery Paradigm Shift is Here

When analyzing disruptive technology, I always focus on first principles. The sodium revolution satisfies two fundamental requirements: it solves real-world problems (safety, fast charging, cold temperature performance) while dramatically improving economics through abundant materials and simpler manufacturing.

CATL's December production timeline is imminent. Their declaration that half of future capacity will be sodium-ion directly challenges the lithium orthodoxy that has dominated energy storage for decades.

The companies and countries that recognize this shift earliest and position themselves accordingly will capture enormous value in the energy transition. Those who dismiss it as an incremental innovation rather than a paradigm shift will be left behind, wondering how they missed one of the most significant technological pivots of our time.